Introduction

One of the most important intersections of civil, chemical, and mechanical engineering is the engineering of a water treatment plant project. It is a science that focuses on converting raw and sometimes polluted surface water into a product that can be of high quality for human consumption by the municipalities or in industries. A modern treatment plant is not just a set of tanks and pipes, it is a complex, integrated system that is able to handle complex chemical reactions and physical separation processes under different environmental conditions.

The most critical phase of the lifecycle of a water utility is the design phase. It involves a profound knowledge of the chemistry of the source water, the estimated needs of the population or industry that it will supply, and the sustainability of the infrastructure over the long term. With the growing global water scarcity and the tightening of regulatory standards, the principles of WTP design will have to change not only to the simple filtration but also to the sophisticated and automated systems that will be able to eliminate new pollutants such as microplastics and pharmaceutical residues. This paper is a detailed technical description of the architectural and operational design needed to construct a stable water treatment plant.

The Significance of the Water Treatment Facility Performance

The main protection of the health of the population and the stability of industries is the functionality of a water treatment facility. In the absence of high-functioning treatment trains, water-borne diseases like cholera and dysentery would always be a menace to the urban population. A properly planned water treatment facility is the kidneys of a modern city, which cleanses the toxins and keeps the homeostasis of the municipal water supply.

In addition to health, the performance of these plants is crucial to the Blue Economy. The semiconductor manufacturing industry, food and beverage processing industry, and power generation industry demand water that is of a certain purity that cannot be obtained through natural sources. When the functionality of a plant is impaired, be it by equipment malfunction or improper design, the economic consequences may be disastrous, resulting in industrial closures and huge financial losses. Moreover, functional efficiency is directly converted to environmental stewardship; plants that perform optimally consume less chemicals and less energy, and this lowers their total carbon footprint.

Standards and Regulations in the Industry

A strict regulatory framework is necessary to make a water treatment plant safe, compliant, and operationally reliable during its 20- to 30-year lifecycle. These standards go beyond mere water quality goals, regulating all aspects of the project, including the structural integrity of pressure vessels to the chemical non-toxicity of hardware components.

The table below offers a multidimensional division of the main international standards that are the “technical blueprint” of the modern water treatment design:

Standard / Code | Definition & Background | Core Category | Primary Function (Why it matters) | Key Requirements & Metrics | Specific Application (Where to use) |

WHO / EPA | Global/National guidelines for drinking water safety. | Water Quality | Defining the Goal: Establishes the legal boundaries for “safe” water. | Sets Maximum Contaminant Levels (MCLs) for heavy metals, pathogens, and DBPs. | Overall process selection (RO, Ultrafiltration, Disinfection). |

NSF/ANSI 61 | Health-based certification for water system components. | Material Safety | Preventing Contamination: Ensures hardware doesn’t leach toxins into the water. | Mandatory Leaching Tests for lead, cadmium, and chemical migration. | Valve linings, O-rings, pump impellers, and pipe coatings. |

AWWA | American Water Works Association infrastructure codes. | Engineering | Lifespan Assurance: Standardizes specs for 20+ years of industrial durability. | Specifies tensile strength, coating thickness, and valve operating cycles. | Distribution piping, large-scale valves, and water storage tanks. |

ASME BPVC | International code for pressure vessel design & manufacturing. | Structural Safety | Hazard Prevention: Eliminates the risk of physical explosion or rupture under pressure. | Minimum wall thickness calculations, NDT weld testing, and relief valve settings. | Pressure filters, activated carbon vessels, and heat exchangers. |

IEC 61508 | The global standard for functional safety of electronic systems. | Automation | Failure Mitigation: Ensures the system reverts to a “Safe State” during power or logic failure. | Evaluates Safety Integrity Levels (SIL 1-4) and MTBF (Mean Time Between Failures). | Emergency Shutdown Systems (ESD) and automated valve loops. |

EN 10204 3.1 | European standard for material inspection documents. | Material Quality | Traceability: Validates that the metal (e.g., 316L SS) meets its claimed properties. | Provides a Material Test Report (MTR) with chemical analysis and mechanical testing. | Valves, pumps, and supports in high-salinity or corrosive environments. |

ISO 9001 | The international benchmark for Quality Management Systems. | Supply Chain | Consistency: Guarantees that mass-produced hardware meets uniform performance. | Requires documented Design Change Controls and rigorous internal quality audits. | Vendor qualification and hardware procurement audits. |

CE / RoHS | Mandatory EU directives for electrical safety and environmental hazards. | Compliance | Safety & Access: Validates electrical safety and limits the use of hazardous materials. | Restricts 10 hazardous substances (e.g., Lead, Mercury) and defines flame retardancy. | Control panels, actuators, sensors, and electronic instrumentation. |

The last step in the translation of a complex design into a high-reliability reality with global certifications is specifying hardware that implements these certifications. The engineers can successfully reduce operational risks, including material degradation, catastrophic pressure failure, or chemical leaching, by choosing components that meet and exceed these benchmarks. Finally, compliance with these standards guarantees the long-term integrity of the operation of the plant and guarantees a sustainable Return on Investment (ROI) throughout the entire service life of the facility.

Design of Water Treatment Plants

The successful plant is the outcome of careful pre-design planning that goes beyond simple engineering. It has to take into consideration a huge number of factors, so that the facility is not only technically sound, but also socially and economically feasible.

Physical Location and Siting

The most basic decisions are the physical location and site of the plant. The plant is ideally supposed to be located at a lower elevation than the source of raw water and higher than the service area. The most faithful friend of the engineer is gravity and by making use of this, the engineer reduces the use of energy consuming pumping which is usually the most expensive operation cost of a utility. Moreover, the location should be located beyond 100-year floodplains and have stable geological features; deep-bore soil testing is necessary to make sure that the ground is able to sustain the huge weight of concrete sedimentation tanks and clearwells without settling unevenly.

Layout and Modular Design

In importance comes layout and modular design. The plant must be designed on the concept of straight-line hydraulics to reduce head loss- the pressure drop that results when water is pushed through turns and bends. The parallel design of the plant in trains, i.e. the same, independent systems, is strongly recommended. This modularity makes sure that in case one train needs some maintenance or suffers a failure, the other parts can still supply water to the community without a complete shutdown of the system.

Strategic Equipment Choice (CAPEX vs. OPEX)

The choice of equipment needs a change of mindset between Capital Expenditure (CAPEX) and Operational Expenditure (OPEX). Although cheap valves and pumps might seem appealing at the bidding stage, they can lead to astronomical costs of maintenance and downtime. Designers ought to focus on high-performance automated hardware that has digital feedback. Corrosive environments such as chemical dosing or desalination areas require materials such as SS316 or special coating to ensure that the equipment can last its 20-year life.

Safety, Containment and Security

The structural fabric of the plant should be integrated with safety and chemical containment. Since water treatment is done with hazardous substances such as sodium hypochlorite or concentrated acids, all storage areas should have secondary containment bunds that can hold 110 percent of the maximum tank volume. In the case of gas-based systems such as chlorine, automated scrubbing systems are required to counter any possible leakages before they escape the containment room. Security is also critical; the design should incorporate physical protection and strong “cyber-hardening” of the SCADA network to avoid unauthorized access to the important valve controls.

Smell, Beauty, and Sound Control

The control of odor, aesthetics, and noise is the most important in ensuring that the plant has a social license to operate, particularly when the plants are close to residential areas. Sludge thickening tanks are covered and bio-scrubbers or carbon filters are used to neutralize hydrogen sulfide to control odors. High-pressure blowers and pumps that produce noise should be placed in sound-dampened acoustic enclosures. To deal with aesthetics, the facility uses so-called industrial camouflage, i.e. landscaping, green walls, and architectural cladding, which makes the facility blend into the surrounding environment instead of a sharp industrial scar.

Effluent Discharge and Waste Management

The effluent discharge standards determine the way the plant handles its own waste. All WTP generate backwash water and chemical sludge which should be treated and then released into the environment. The design should have a special train called the residuals train which will concentrate the wastes by thickening and dewatering. The liquid that results should comply with the local environmental regulations, and the solid cake should be stable to be disposed of in a landfill.

Water Treatment Processes and Treatment Train

The logical series of operations that is used to transport water between the raw and the potable is the treatment train.

Intake & Pre-treatment

The process of purification starts with the abstraction of raw water, where water is pulled through protective trash racks and fine traveling screens to keep out debris, plastic and aquatic life; pre-oxidation agents such as ozone or chlorine are added to keep out dissolved minerals such as iron and manganese and prevent biological growth in the internal piping of the plant. Intake velocities are kept to a minimum of 0.15 m/s to avoid impingement of fish and other aquatic organisms to ensure compliance with the environment and to protect the local ecosystems.

Coagulation, Flocculation & Sedimentation

The plant uses high-energy flash mixing to distribute coagulants such as Alum to neutralize the electrical charges of the microscopic suspended particles that are too light to settle on their own. This is then followed by a low energy, gentle flocculation phase that promotes the collision of these neutralized particles to create heavier flocs, which are then effectively removed by gravity in sedimentation basins, commonly fitted with lamella plate settlers to maximize the effective settling area without increasing the physical footprint of the facility.

Filtration (Gravity, Pressure, Membrane)

After the solids have been removed in large quantities, the clarified water is then filtered to trap any fine particles and pathogens. This is done by either the use of the old fashioned gravity sand filters using layers of anthracite and sand or by the use of the modern membrane filtration systems (Ultrafiltration or Microfiltration) which is an absolute physical sieve with a pore size of 0.01 microns or less to effectively prevent bacteria and viruses to pass through the treated water supply.

Advanced Polishing (GAC, Ion Exchange, RO, AOP)

In the case of water sources that have dissolved organics, salts, or emerging chemical contaminants, more advanced polishing steps like Granular Activated Carbon (GAC) adsorption or Reverse Osmosis (RO) are used to remove odors, pesticides, and salinity on a molecular level. In more complicated cases, Advanced Oxidation Processes (AOP) are used to combine UV light with hydrogen peroxide to form hydroxyl radicals which literally shred stubborn chemical pollutants, so that the end product is of the highest purity.

Disinfection & Storage

The last obstacle to waterborne disease is a strict disinfection process in which chlorine, chloramines, or UV reactors are employed to obtain the required level of Contact Time (CT value) in baffled clearwells. This step is not only meant to kill any remaining pathogens but also to leave a secondary residual disinfectant in the water as it flows through miles of distribution piping, so that it is safe and sterile until the time it reaches the tap of the consumer.

Residuals & Solids Handling

A responsible treatment train should also dispose of the waste it produces by diverting chemical sludge and filter backwash water to a special residuals train. In this case, the waste is collected in thickeners and then treated using dewatering equipment such as centrifuges or belt filter presses to create a stable and solid cake that can be disposed of in landfills, and the liquid filtrate that is collected is recycled to the beginning of the plant to maximize water use and reduce environmental discharge.

Essential Systems and Infrastructure

A WTP is a complicated machine and it needs a number of life support systems:

Hydraulic Distribution and Flow Control: The hydraulic system of the facility is based on a system of robust, corrosion-resistant piping, including epoxy-coated ductile iron or HDPE, and high-precision valves that ensure the flow velocities are kept at their optimum and the pressure drops across the entire treatment chain are minimized to waste energy.

Electrical Systems and Energy Management: Dependable electrical infrastructure will use Variable Frequency Drives (VFDs) to optimize pump energy use depending on real-time demand and will have backup power sources to ensure that important disinfection processes can continue even in the event of a complete grid outage.

Automation and SCADA Control Networks: The SCADA architecture is the central nervous system of the plant, which uses the so-called cyber-hardened programmable logic controllers (PLCs) and real-time data visualization to enable operators to control all the motors, sensors, and valves remotely, in a secure and centralized location.

Chemical Storage and Precision Dosing: High-precision metering pumps are used with secure secondary containment “bunds” to guarantee proper reagent injection and provide a physical barrier to protect personnel and the environment against dangerous leaks or spills.

Monitoring and Analytical Instrumentation: A full sensing network uses in-line instruments to give real-time feedback on key water quality parameters such as turbidity, pH, and chlorine residuals, enabling the plant to automatically adjust levels of treatment or divert off-spec water.

Civil Structures and Structural Integrity: Large civil structures such as reinforced concrete sedimentation basins and storage clearwells are designed with special liners and sulfate-resistant materials to resist decades of continuous liquid pressure and environmental stress without structural collapse or leakage.

Design Calculations and Hydraulic Considerations for Efficient Plant Operation

Hydraulics is the circulatory system that is invisible in a water treatment facility. It is not enough to design a plant that is up to the water quality standards, the task is to make the system run without bottlenecks, use as little energy as possible, and last years of varying demand. In order to do this, engineers need to go beyond the treatment process and consider the physics of the flow.

Reduction of Energy Loss: Head Loss and System Pressure

Your plant has every pipe, valve, and filter, which can be a source of energy loss. Friction results in a decrease in pressure as water flows through these parts- Head Loss. When such calculations are not accurate, you may end up with pumps that are unable to deliver the necessary flow or on the other hand, oversized pumps that will increase electricity bills and may fail to work.

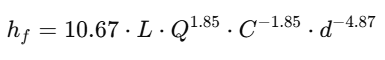

The Hazen-Williams Equation is the industry standard of calculating this friction:

(Where L is the length of the pipe, Q is the flow, C is the coefficient of friction and d is the diameter.)

Practically, the less head loss you have, the less Total Dynamic Head (TDH) you have, and the less your monthly OPEX will be. To maximize this, the strategic decision is to define pipes with high C values, including HDPE or UPVC, which retain their smoothness during decades of operation. Also, when laying out, it is possible to substitute sharp 90 o bends with long-radius elbows, which can greatly decrease turbulence, and in many cases, a 10-15 percent decrease in pumping energy needs can be achieved.

Optimization of Hydraulic Retention Time (HRT): The Biological Clock

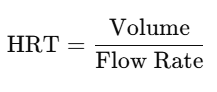

Consider HRT to be the contact time that chemistry and physics need to work. It can be a disinfection chamber or a sedimentation tank, but water should remain in the unit long enough to allow chemical reactions or to allow the settling of particles. The wrong volume calculations cause short-circuiting, in which untreated water does not pass through the primary treatment zones and leaves the plant too soon.

The fundamental math is:

In addition to increasing the size of the tank, which is costly and occupies space, performance can be enhanced greatly by controlling the flow of water in that volume. The baffle walls or serpentine flow designs must be integrated to make sure that the full cubic capacity of the tank is utilized. This eliminates dead zones and enables a smaller, more economical footprint to provide the same water quality as a significantly larger, inefficiently designed tank.

Gravity vs. Velocity: The Surface Overflow Rate (SOR)

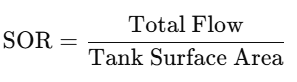

The effectiveness of a clarifier is a fine balance: the velocity of the water upwards and the settling velocity of the waste particles downwards. This is the Surface Overflow Rate (SOR). When the upward flow is excessively rapid, it will defeat the force of gravity and drag the floc (sludge) into your filters, clogging them and necessitating frequent and costly backwashing.

Calculated as:

The most effective protection of your downstream filters is a stable SOR. By retaining solids in the clarifier, you increase the life of your filter media and conserve thousands of gallons of water that would otherwise be wasted in backwashing. In projects that have small real estate, Lamella Clarifiers (Slanted Plate Settlers) is the best design option. These units make use of stacked plates to increase the effective settling area, enabling you to process high flow rates in a fraction of the area.

The Powerhouse: Pump Mapping and the Best Efficiency Point (BEP)

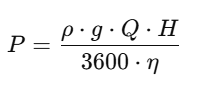

Pumps are the biggest single item in the energy bill of a plant. Each pump is intended to possess a Best Efficiency Point (BEP) the sweet spot at which it transforms electricity into flow with the least amount of wasted energy. Operating a pump outside of its BEP will result in excessive heat, vibration, and early bearing or seal wear.

Engineers measure this performance by Specific Energy Consumption:

(Where n is the coefficient of efficiency.)

To ensure efficiency in different flow conditions, it is important not to throttle the flow using valves because this will result in huge hydraulic wastage. Rather, require the use of Variable Frequency Drives (VFDs). A VFD enables the motor to vary its speed to satisfy real-time demand whilst maintaining the pump as near to its BEP as possible. This strategy can reduce energy usage by as much as 30 percent and unscheduled downtime is greatly minimized.

Design Validation and Performance Testing: Pilot Runs to Plant Commissioning

Although the last test is field commissioning, the integrity of a WTP is initially ensured in the digital design stage by intensive simulation and stress-testing. After the construction is finished, the theoretical modeling is replaced by the validation of the operational performance of the plant against its design benchmarks. This stage removes hydraulic bottlenecks and streamlines operational costs (OPEX) prior to the plant going into full scale service.

Dry Commissioning: Component Integrity: Engineers conduct loop testing before adding water to the system to verify that the SCADA system can communicate with level sensors and automated valves. Checking motor rotation and mixer positioning at this point will avoid mechanical damage during the first fill. This dry run will ensure that the automation logic of the plant is prepared to deal with the real-world hydraulic loads.

Hydraulic Load Testing: HGL Validation: The Hydraulic Grade Line (HGL) is validated by filling the system with clean water. Engineers ensure that the real Head Loss is equal to the design by measuring the water levels at peak flow. This is essential in determining physical bottlenecks like unanticipated friction in valves that may lead to upstream overflows or pump cavitation.

Process Stabilization and Chemical Fine-Tuning: After stabilizing hydraulics, theoretical dosing rates are substituted by real-time data. You can save a lot of chemical waste by optimizing the dosages of Velocity Gradient (G-value) and coagulant dosages, depending on the real quality of raw water. In this process, operators stabilize the sludge blanket in clarifiers to stabilize the Surface Overflow Rate (SOR) to ensure that solids do not clog downstream filters.

Performance Guarantee Testing (PGT): The PGT is a full-capacity run (usually 72 hours to 7 days) to demonstrate that the plant is up to its design standards. In addition to water quality, it certifies Specific Energy Consumption (kWh/m 3). When the energy consumption is higher than the targets, it usually means that the pumps are not working at their Best Efficiency Point (BEP), and they need to be adjusted to ensure the long-term sustainability.

Operational Readiness and Benchmarking: Commissioning ends with the creation of a “Performance Benchmark.” Recording the precise power and chemical yields obtained in the PGT is a benchmark in troubleshooting in the future. This information, when incorporated in the Standard Operating Procedures (SOPs), will make the operations team capable of sustaining the designed efficiency of the plant throughout its lifecycle.

Common Pitfalls and Risk Mitigation Strategies

In order to make a water treatment plant reliable in the long term, the designers should go beyond general precautions and focus on engineering oversights that cause the failure of the system. With these technical pitfalls identified and mitigation strategies built into the infrastructure, a facility can remain compliant even when subjected to extreme operational stress.

Ignoring Seasonal Source Water Variations: It is a common trap to design the treatment train using average water quality data, which often leads to an overloaded plant due to seasonal peaks in turbidity during heavy runoff or unexpected algae blooms. To reduce the risk, it is necessary to install the so-called adaptive dosing systems, which are connected with real-time raw water sensors and the introduction of pre-sedimentation basins or Dissolved Air Flotation (DAF) units, which will enable the plant to withstand sudden increases in the solids loading without deteriorating the quality of the effluent.

Weaknesses in Hydraulic Surge Protection: Most plants experience disastrous bursts of pipes or joints due to the design not taking into consideration the so-called water hammer, which is the high-pressure shockwave generated by the sudden failure of the pump or the sudden closing of a valve. This risk is addressed by incorporating surge vessels and air-vacuum release valves at the high points in the pipework, as well as the application of Variable Frequency Drives (VFDs) to provide a soft-start and soft-stop sequence to ensure the structural integrity of the whole hydraulic network.

Material Degradation and Chemical Incompatibility: The use of lower grade alloys or standard coating in chemical dosing areas is likely to result in rapid corrosion and unplanned downtime, especially with aggressive reagents such as ferric chloride or sodium hypochlorite. High-performance materials like Duplex Stainless Steel, Fiber Reinforced Plastic (FRP) or special thermoplastic liners should be used in all wetted parts by engineers so that mechanical components can survive corrosive conditions throughout their entire 20-year design life.

Automation Failures and Actuator Reliability: The most dangerous failure mode in a modern plant is the loss of flow control in the event of a power outage or system crash, which may cause dangerous chemical overflows or clearwell flooding. To overcome this, critical process points should use high-performance automated valves with fail-safe actuators (pneumatic spring-return or battery-backup electric). The twofold benefit of these automated solutions is that they provide the control of the flow with accuracy to minimize the waste of chemicals and the ability to monitor the situation remotely without the necessity of hazardous manual intervention in case of an emergency.

The last step in making these design strategies come to fruition in a high-efficiency, reliable reality is the choice of precision-engineered hardware such as the automated valves of Vincer.

Vincer Precision Automated Valves: The Secret of Long-term Plant Reliability

The design of a high-performance water treatment can only be as reliable as the valves that implement its logic. Vincer fills the gap between complicated engineering and field reality by providing more than 20 special sub-categories of automated valves, all made of high-grade raw materials and high-quality imported seals. These parts are specially designed to resist the high temperatures, abrasive media and corrosive conditions of the modern treatment facilities, greatly increasing the service life of the system.

A solution-driven approach is what makes Vincer stand out. With more than ten years of experience in the industry, our engineering team applies a thorough 8-dimensional analysis, which considers medium, pressure, temperature, and environmental factors, to make each valve a perfect fit to its application. This careful attention to detail is justified by a system of global standards, such as ISO 9001, CE, SIL, and FDA certifications, which guarantee complete adherence to international safety and quality standards.

Vincer offers preliminary technical proposals within 24 to 48 hours by simplifying procurement by using a one-stop service model. We enable designers to save capital spending without compromising on accuracy, providing a high-efficiency substitute to conventional global brands. When you are sourcing a component with Vincer, you are not merely sourcing a component, but a proven engineering solution designed to operate with long-term uptime.

Digital Design Tools and Software for Water Treatment Plant Engineering

Digital integration is no longer a luxury in the contemporary world of water treatment plants design, but it is the cornerstone of project success. These software solutions serve as the digital nervous system of an engineering project, between the theoretical calculations and the long-term operational reality. Moving past the 2D drawings to the 3D models with data can enable engineers to forecast performance, eradicate construction conflicts, and greatly optimize capital and operational expenditures.

Software / Tool | Project Phase | Core Role | Key Technical Features | Typical Pain Points Solved | Strategic Impact (Value Proposition) |

BioWin / GPS-X | Conceptual & Process Design | Process Simulation & Validation | Dynamic modeling of biological/chemical processes; “Stress-testing” against nutrient fluctuations. | Prevents inaccurate process sizing and the risk of non-compliance during peak hydraulic loads. | Optimizes OPEX: Eliminates equipment over-design and minimizes chemical/energy consumption. |

AutoCAD Plant 3D | Detailed Engineering | Spec-Driven Modeling | Intelligent P&IDs linked to 3D models; Automated Bill of Materials (BOM) generation. | Solves the discrepancy between P&IDs and physical builds; prevents incorrect valve or pipe material specs. | Ensures Construction Accuracy: Guarantees a 1:1 match between process logic and physical installation. |

Autodesk Revit (BIM) | Multidisciplinary Coordination | BIM Hub & Clash Detection | Integrated structural, mechanical, and electrical modeling; Automated spatial interference scanning. | Eliminates “pipe-vs-beam” conflicts and ensures adequate clearance for pump maintenance and valve access. | Reduces Field Rework: Resolves physical conflicts digitally, saving weeks of construction delays and costly change orders. |

Digital Twins | Operations & Maintenance (O&M) | Asset Management & Virtual Ops | Integration of real-time sensor data with 3D models; Virtual access to maintenance history and manuals. | Replaces hard-to-navigate paper manuals; solves the problem of reactive, “break-fix” maintenance cycles. | Maximizes Uptime: Enables predictive maintenance and virtual repair training, enhancing overall plant safety and reliability. |

Beyond Compliance: Advanced Technologies and the Development of the Smart Plant

With the changing engineering standards, the contemporary water treatment plant is being re-defined as a high-tech resource recovery centre. To achieve success in this new environment, a combination of accuracy-focused hardware and predictive digital intelligence is needed to guarantee long-term operational resilience and efficiency.

High-Performance Membrane Filtration and Water Reclamation: The design has changed to the modern design where wastewater is treated as a secondary water source and not as a byproduct. The most recent technologies, including Ultrafiltration (UF), Reverse Osmosis (RO), and Membrane Bioreactors (MBR) are now the heart of high-performance plants, which act as water refineries. With high-density membrane configurations, engineers are able to recover water to industrial or even potable quality in a much smaller physical footprint, and 1:1 water reuse is a design goal.

Zero Liquid Discharge (ZLD) and the Circular Economy: Zero Liquid Discharge (ZLD) is becoming a critical design requirement of industrial infrastructure to comply with the most stringent environmental requirements. These systems employ high-level evaporation and crystallization to reclaim up to 99 percent of wastewater, which essentially removes liquid discharge. In addition to waste reduction, next-generation ZLD designs are oriented at so-called mineral harvesting, where valuable salts and chemicals are extracted out of the brine to convert treatment burdens into revenue streams of the circular economy and safeguard the local ecosystems.

AI and IoT: The Rise of the Predictive “Smart Plant”: The development of the “Smart Plant” is a step forward in the evolution of the reactive monitoring system to the predictive control based on AI. With the implementation of a high-density network of IoT sensors, facilities will be able to process real-time influent data and weather conditions to predict shock loads before they hit the intake. This intelligence enables independent optimization of chemical dosing and energy use. Implementing these milliseconds adjustments needs high-performance hardware, including Vincer smart actuators, which offer the accuracy and digital feedback to keep the system in balance during unstable conditions.

Digital Twins and Real-Time Performance Simulation: Digital Twins, which are dynamic, data-fed simulations of the physical facility, are now being used in modern engineering to operate the entire lifecycle of the asset. These models enable operators to conduct virtual what-if simulations to determine the effects of process changes without jeopardizing the stability of the plants. The Digital Twin can detect the slightest performance changes in pumps or membranes before a physical failure takes place, moving the facility towards a predictive maintenance model, maximizing the design life of all components, and guaranteeing 100 percent operational uptime.

The water treatment trend is decisively shifting towards a closed-loop ecosystem that is entirely autonomous and in which the facilities default to recovery of resources instead of disposal. The water treatment plants of the future will be self-educating resource centers by integrating the predictive capabilities of digital intelligence with the accuracy of high-performance hardware. Not only will these facilities produce almost zero environmental impact, but they will also offer a robust, data-driven basis of global water security and sustainability.

Conclusion

The process of designing a water treatment plant is a high stakes project that has to balance the demands of engineering with the demands of serving the people. Since the first intake to the last disinfection, each step should be calculated accurately and constructed using elements that can stand the test of time. Following international standards, applying the latest digital tools, and choosing trusted partners to work with the most important infrastructure, such as automated valves, engineers can make sure that the most valuable resource will be safe, clean, and available to the generations to come.

FAQS

Q: What is the design of a water treatment plant?

A: Examine the quality of source water, establish effluent objectives, choose the treatment process train, conduct hydraulic sizing, and incorporate automated control systems.

Q: What would it cost to construct a water treatment plant?

A: The cost depends on the daily flow capacity (MGD), the sophistication of the treatment technology, the local land/labor rates, and the degree of automation needed.

Q: What are the 7 processes of a water treatment plant?

A: The seven steps include intake, screening, coagulation/flocculation, sedimentation, filtration, disinfection and final storage/distribution.

Q: What are the chemicals applied in the treatment of water?

A: Some of the common chemicals are coagulants (alum), pH modifiers (lime or soda ash), disinfectants (chlorine or ozone), and fluoridation agents.